GST : 24ANUPP3656Q1ZY

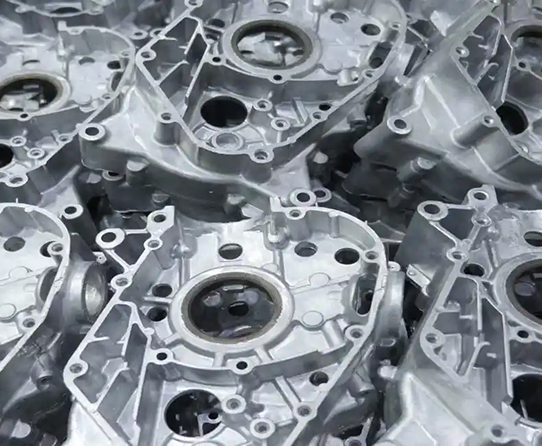

Die Castings of best quality of Aluminum Die Casting, Pressure Die Castings, Gravity Die Castings at reasonable price.

Studying conditions of the markets, analyzing needs of the customers, assuring complete satisfaction of the customers, encouraging employees for better productivity and excelling in work performance is how Alucast Industries is expanding largely in the industry.

Our company is 2012 formed and devoted to working as a manufacturer and supplier to provide customers nothing below the best in products like Aluminum Die Casting, Pressure Die Castings, Gravity Die Castings and Zinc Die Casting.

2012

Year of Establishment

Business

Manufacturer

15

No of Staff

Lets

Talk Business

Please take a quick moment to complete this

form a business representative will get back to you swiftly

User Name

Phone

SubJect

Message

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free