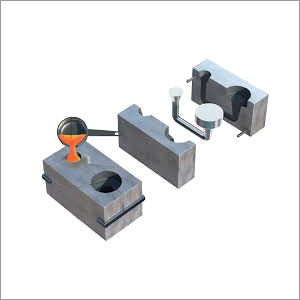

Aluminum Gravity Die Casting

Price 70 INR/ Unit

MOQ : 1000 Units

Aluminum Gravity Die Casting Specification

- Usage

- INDUSTRIAL

- Material

- Aluminum

- Application

- Industrial

- Processing

- Gravity Die Casting

- Surface

- Other

- Product Type

- Aluminum Gravity Die Casting

- Machining Type

- CNC Machining

- Heat Treatment

- Optional

- Tolerance

- up to 0.05 mm

- Hardness

- 50-120 HB

- Casting Weight Range

- up to 50 kg

- Corrosion Resistance

- High

- Customization

- Available as per drawings

- Dimension Accuracy

- High

- Shape Complexity

- Medium to high complexity

Aluminum Gravity Die Casting Trade Information

- Minimum Order Quantity

- 1000 Units

- FOB Port

- VADODARA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5000 Units Per Week

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Aluminum Gravity Die Casting

We are widely recognized as the leading manufacturers and suppliers of the Aluminum Gravity Die Casting in market for our unmatched quality standards. It is fabricated by utilizing the premium grade raw materials under surveillance of highly advance technologies in order to ensure its flawless structural design. It is small and allows easy installation. It is highly resistant to corrosion and demand no maintenance. Offered Aluminum Gravity Die Casting is extremely durable and accessible as per requirements at cost efficient range of prices.

Precision and Strength for Industrial Needs

Our aluminum gravity die casting combines high dimensional accuracy with substantial hardness, supporting industrial environments that demand reliability and strength. Medium to highly complex shapes are cast flawlessly, and our processes deliver a sleek metallic finish, essential for professional-grade applications. With a tolerance of up to 0.05 mm, we guarantee precision in every product.

Expert Customization and CNC Machining

Clients can request custom castings based on specific drawings and industrial requirements. Our CNC machining capabilities ensure consistency across every unit, enhancing usability in critical applications. Optional heat treatments are available to further tailor the mechanical properties, all according to your project specifications.

Corrosion Resistance and Long-Term Value

Built from high-quality aluminum, our gravity die cast components offer excellent corrosion resistance, making them suitable for demanding industrial climates. Each casting maintains its integrity and performance over time, providing dependable solutions for manufacturers, suppliers, and exporters across India and beyond.

FAQs of Aluminum Gravity Die Casting:

Q: How does the gravity die casting process ensure high dimensional accuracy and surface finish in aluminum components?

A: Gravity die casting uses controlled mold filling and solidification to achieve tight tolerancesup to 0.05 mmwhile CNC machining refines the final product. The result is a smooth, metallic finish with precise dimensions suitable for industrial needs.Q: What shapes and sizes can be achieved with your aluminum gravity die casting service?

A: We can produce aluminum castings with medium to high complexity and weights up to 50 kg. Customization is available according to provided drawings, accommodating a wide range of industrial applications.Q: When is heat treatment recommended for these aluminum castings?

A: Heat treatment is optional and typically recommended when increased hardness or specific mechanical properties are required for demanding industrial usage. Our team can advise based on your application needs.Q: Where do you supply and export aluminum gravity die cast components?

A: We operate as a manufacturer, supplier, distributor, exporter, and wholesaler out of India, serving both domestic and international industrial clients seeking premium aluminum castings.Q: What are the main benefits of using aluminum gravity die castings in industrial applications?

A: Our castings are valued for their high corrosion resistance, dimensional accuracy, customizable designs, and consistent qualityall crucial for reliable industrial operations over extended periods.Q: How does your customization process work for aluminum cast components?

A: Clients submit their technical drawings or specifications, based on which we design and manufacture the customized aluminum parts. Our production process includes optional heat treatments and CNC machining for enhanced properties.Q: What industries typically use your aluminum gravity die castings?

A: These castings find applications in sectors such as machinery, automotive, electrical enclosures, and other industrial manufacturing, owing to their durability, precision, and resistance to harsh environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free